You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Laminate for my 54XL

- Thread starter Jean-Marc Dugas

- Start date

Don't forget the pattern in you lay out. Noticed this when rebuilding the cabinet on the 70. You rotate one of those doors you might as will Paint it orange. It really sticks out.

Jean-Marc Dugas

PCS Member

Yes. Each template is also marked with the direction of the pattern.Don't forget the pattern in you lay out. Noticed this when rebuilding the cabinet on the 70. You rotate one of those doors you might as will Paint it orange. It really sticks out.

Jean-Marc Dugas

PCS Member

I just ordered two 5x12 sheets of Gloss White Ash from Formica. They should be here in 2 to 6 weeks. I'll now get cheap laminate and practice the cutting and application process on whatever I can put my hands on.

I thought i was doing good getting this 70 togather. Discovered CB didn't pay any attention to grain on one door. I swair i took it apart 4 times rotating it around before i could get all 3 hinged panels to open and close with out dragging.

Jean-Marc Dugas

PCS Member

Will that looks good. I don't remember if superior beveled the edges like The Wayne coaches were

Jean-Marc Dugas

PCS Member

I hope it will look good for the price I paid for it!Will that looks good. I don't remember if superior beveled the edges like The Wayne coaches were

All of the laminate edges are at 90 degrees.

Jean-Marc Dugas

PCS Member

Laminator training has started. Binge watches a whole bunch of YouTube videos, went to Home Depot to buy a few tid bits, ordered a couple of laminate specific tools off Amazon, the weekend warrior is ready!

With what I have on hand I laminated a small piece of wood from the scrap pile. Not bad for a start, learning lots.

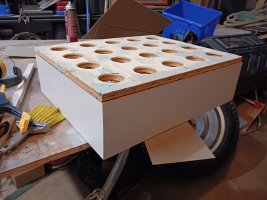

Next I will laminate my scent detection training box. This box has many of the same issues as the wood I will need to work with on the car, so why not!

I started with the bottom of the box which was relatively intact.

I'll take the box apart today and tackle it piece by piece.

With what I have on hand I laminated a small piece of wood from the scrap pile. Not bad for a start, learning lots.

Next I will laminate my scent detection training box. This box has many of the same issues as the wood I will need to work with on the car, so why not!

I started with the bottom of the box which was relatively intact.

I'll take the box apart today and tackle it piece by piece.

How are you going to deal with the chamfered holes?

Jean-Marc Dugas

PCS Member

First I have to deal with the imperfections on that piece. I smoothed it out with the belt sander and filled some of the dents and broken corners with Bondo. I will belt sand it again tomorrow and may have to work on the prep some more so that it glues really good.How are you going to deal with the chamfered holes?

Once the laminate is glued solid, it "should" just be a matter of punching through each holes and the running a chamfer bit with the router.

Jean-Marc Dugas

PCS Member

After the top sheet was glued in place I used the router to clean the edges of the box and marked roughly where the centre of each hole was. I used a screwdriver to punch a hole in the middle of each hole large enough to insert the flush mount rotor bit and made a first pass. This removed the laminate flush with the inner part of the hole. Once all of the holes were done, I switched to the beveled router bit and worked all of the holes again. This worked really well.How are you going to deal with the chamfered holes?

I still need to chamfer the edges of the box so that there are no edges that stick oit and get caught and rip off as well as give it a good clean-up before I put it back together.

This is definitively not a museum piece, the box has been in use for training for several years and was made our of left over plywood so the edges are not squares and is overall a little beat-up, so it was hard to get sharp edges with the laminate. However I learned enough to know that I definitively need to do at least one other practice run before I tackle the ambulance.

Looks a lot better then it did. But the dog will have the final say. If he refuses to use it you know you need to do another one.

Jean-Marc Dugas

PCS Member

Yep!Looks a lot better then it did. But the dog will have the final say. If he refuses to use it you know you need to do another one.

Jean-Marc Dugas

PCS Member

There is now no turning back now!

I decided to go with a heat gun to remove the laminate instead of soaking it with paint thinner. Worked well on these three items.

I did not really thought about this until today, but since all of the laminate pieces are coming off relatively intact, they will be the perfect template for the replacement parts.

I decided to go with a heat gun to remove the laminate instead of soaking it with paint thinner. Worked well on these three items.

I did not really thought about this until today, but since all of the laminate pieces are coming off relatively intact, they will be the perfect template for the replacement parts.

Jean-Marc Dugas

PCS Member

Using paint thinner and a scrapper to remove the excess glue and then sanding the rest to get to the wood. I'll have to fill in the spots where the wood is chipped with Bondo and make sure that all of the corners are sharps.

The bottom front of the cabinet is damaged because the extruded aluminum sliders were screwed too close to the edge. I'll have to make sure to screw the sliders through the back slide instead of the front.

The bottom front of the cabinet is damaged because the extruded aluminum sliders were screwed too close to the edge. I'll have to make sure to screw the sliders through the back slide instead of the front.

Attachments

Philip Scanio

PCS Member / Super Site Supporter

Your attention to detail is incredible. Congratulations on this noble project.

Jean-Marc Dugas

PCS Member

I did a little testing with Acetone, Paint Thinner and Robert's 5505 to see what would work better and the Robert's product won the race hands down.

I will still have to sand the surface once the solvent dries out, but this Robert stuff works excellent!! The second photo is after 2 applications of 5505 which I leave in place for about 30 minutes before using a small scrapper to remove the glue and then a go over with steel wool.

I will still have to sand the surface once the solvent dries out, but this Robert stuff works excellent!! The second photo is after 2 applications of 5505 which I leave in place for about 30 minutes before using a small scrapper to remove the glue and then a go over with steel wool.

Jean-Marc Dugas

PCS Member

Don't forget mixing time. The more you play with it the faster it sets up.