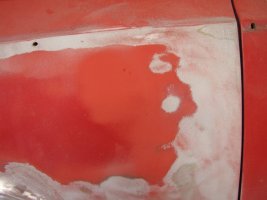

Close to it. The side under the molding has been painted 3 times above it twice, the top twice, all different shades.

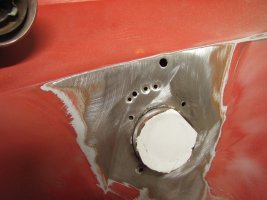

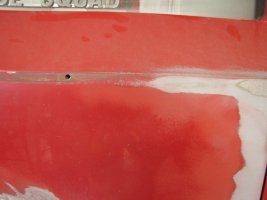

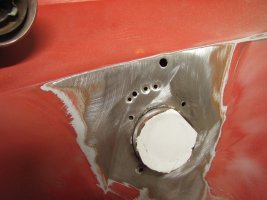

We then worked on finishing the repair in the wheel well and cleaning up the quarter, preparing it for priming. Found more pin holes above the gas cap. More moisture is trapped under the dried-out coating coming down from the molding. They replaced the plastic with spring clips sometime in the past, so water could leak into the panel with no way out. Decided to dimple them and use all metal. Rather than risk a fire. Found a spot around the taillight where the thickness of paint had cracked, and water had crept under the paint. It had been painted over. One of the reasons we are going to thin the paint down to the primer over most of the car. The other is film thickness and a million chips. We are trying to preserve this car, not just give it a temporary pretty face.

We then worked on finishing the repair in the wheel well and cleaning up the quarter, preparing it for priming. Found more pin holes above the gas cap. More moisture is trapped under the dried-out coating coming down from the molding. They replaced the plastic with spring clips sometime in the past, so water could leak into the panel with no way out. Decided to dimple them and use all metal. Rather than risk a fire. Found a spot around the taillight where the thickness of paint had cracked, and water had crept under the paint. It had been painted over. One of the reasons we are going to thin the paint down to the primer over most of the car. The other is film thickness and a million chips. We are trying to preserve this car, not just give it a temporary pretty face.