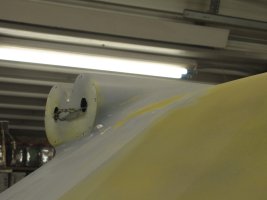

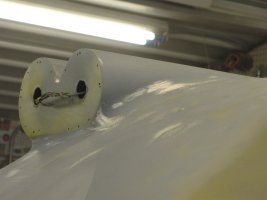

Got a call from the boss today; he said, "Take that CB antenna out." I said, "Can't get to it." He said, "Look up." So, I did, and I did. decided to solder the patch in place rather than use a lot of heat. The hard part was finding someone to hold it. While things were cooling off, I blocked off the spots we primed on Wednesday. had to drop everything and go rescue a friend who broke down. Got him towed to a safe spot and finished taping off the car. Put a gallon of primer on the top. Then shot it yellow. Honest, I thought he said yellow. Guess we can sand it off later. The snow arrived right on time. We'll see if we get the 4 inches they ordered for us.