John ED Renstrom

PCS Member

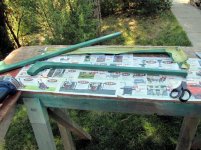

I know most of us would like to be able to go back and work in the factory our cars were built in. it would be really keen to be able to stand in the finaly assembly floor and watch them go to gather even better to be doing it hands on. but it would just be my luck the only opening would be it this department. and I stand there all day doing this one part one time in green next in blue, another red, one white, then back to green and on to a tan one. I tell you I would end up insane in a short order.