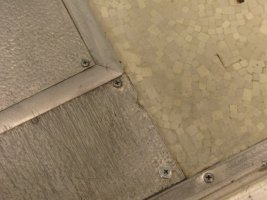

so what can we do about it except change it or live with it? it it's sun rotter and all dried out split and peeling change it you must. but what about those strange stains the gurney scratches the aluminum bar rubes and just general wear and tear? let me show you a housekeeping trick or two. if your going for a knock out pull the trim around the edge and buff it toss those striped-out screws and those missed matched on barely holding the hinges on that hatch and folding seat. set and get some3 inch Number 6 X head screws. no bigger is not the answer longer is. dip them in some glue and zip them in starting from the center and working out. the good news is the original linoleum has the pattern clear threw it. you new vinyl is only on the surface and is throw-away stuff. the original you can sand imperfections out of. so if it really rough start with 80 grit on the bad spots and work your way up. I have removed some nasty things from the floor. this 77 was just well used. I don't know what was under the Aluminum patch panels so think you just let lay but if it's scared up down to the wood this is one way to salvage what you can. so we started with 180 on this floor and went up to 400. and the red scotch pad as our final scuff. with our soap and water scrub