You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

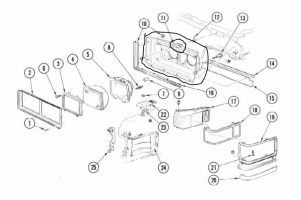

1975 - 1976 Fleetwood Headlight Housings

- Thread starter Jean-Marc Dugas

- Start date

I ,ll keep an eye out, but those are getting harder to find. Make sure all the shims are back in place when you install the new ones.

Jean-Marc Dugas

PCS Member

Thanks Dan. From what I have seen on eBay and a few other sites the majority have the same problem as mine with the broken upper tab.I ,ll keep an eye out, but those are getting harder to find. Make sure all the shims are back in place when you install the new ones.

I got lucky and found a set for the 75, they do show up in the yards occasionally.

Kurt Arends

PCS Elected Director 2021-2024

EXTREMELY hard to find perfect examples anymore. It seems that body/paint guys are bad at counting shims. I can check to see what I have, but not overly motivated to sell any of them. When did you paint your ambulance blue???

Crazy idea #97843971. In 2021 there are thousands of homeshop guys with 3D printers looking for short run jobs. It's become a minor industry on machinetool sites.

I see no reason something like that headlight assembly can't be printed if you have the pieces of the broken original that can be glued back together for a pattern.

I see no reason something like that headlight assembly can't be printed if you have the pieces of the broken original that can be glued back together for a pattern.

Jean-Marc Dugas

PCS Member

Still orange. The picture is from e-bay.EXTREMELY hard to find perfect examples anymore. It seems that body/paint guys are bad at counting shims. I can check to see what I have, but not overly motivated to sell any of them. When did you paint your ambulance blue???

Jean-Marc Dugas

PCS Member

The cost of designing the headlight assembly in a 3D design software and then 3D printing it out of metal would most likely be more than what they can be bought for on eBay. My experience with 3D printing (plastic not metal) is that a lot of time is spent designing the pieces. It is fun, but takes a lot of time. Even if one has a 3D scanner, there would still be hours of work cleaning up the file so it is ready for printing.Crazy idea #97843971. In 2021 there are thousands of homeshop guys with 3D printers looking for short run jobs. It's become a minor industry on machinetool sites.

I see no reason something like that headlight assembly can't be printed if you have the pieces of the broken original that can be glued back together for a pattern.

Now you can clean up the tab to get both sides to look the same and decent. Clean off the excess casting so there is no trace of them. It was a poor choice of product To us to attach them. The steel tabes dont brake with expansion and contraction.

Jean-Marc Dugas

PCS Member

If I do that and do not replace them with an L bracket, would it not affect the alignment of the whole headlight assembly?Now you can clean up the tab to get both sides to look the same and decent. Clean off the excess casting so there is no trace of them. It was a poor choice of product To us to attach them. The steel tabes dont brake with expansion and contraction.

There goes my sole chance to add Idea Man to my business cards.

Revision W says build the tab with JB Weld.

Revision W says build the tab with JB Weld.

Jean-Marc Dugas

PCS Member

Most likely, unless I want to spend a ridicuus amount of $$There are only 3 points where the whole assembly mounts. 2 on the bottom and 1 on top. As long as it is secure with a strap etc. it will work. Just chk the headlight alignment.

View attachment 47134

I have a 90% bracket in place that holds the assembly in place. I would prefer to have the assembly intact, but for now it will have to do unless I can find something at a reasonable price.There are only 3 points where the whole assembly mounts. 2 on the bottom and 1 on top. As long as it is secure with a strap etc. it will work. Just chk the headlight alignment.

View attachment 47134

You line the housing with the other panels. The lights are adjusted with the headlight adjusters on each bulb. That is a lot of weight on the one tab of pot metal. GM getting cheap . All the shims are for is to line it up with the hood. I have yet to see the l shaped add on ones fail no matter how crude they look.